Freezing

There are various methods to freeze the product. Freezing can be done in a cold bath, in a refrigerator, or directly on a shelf in the freeze dryer. Cooling the material below its triple point ensures that the product is sublimated rather than thawed. The shape of the product is thus retained in the best possible way.

Large ice crystals created by slow freezing are the easiest for the freeze dryer to dry. However, if the crystals are too large, they can destroy the product’s cell walls, resulting in a lower quality end product. To prevent this, the freezing process is carried out as quickly as possible.

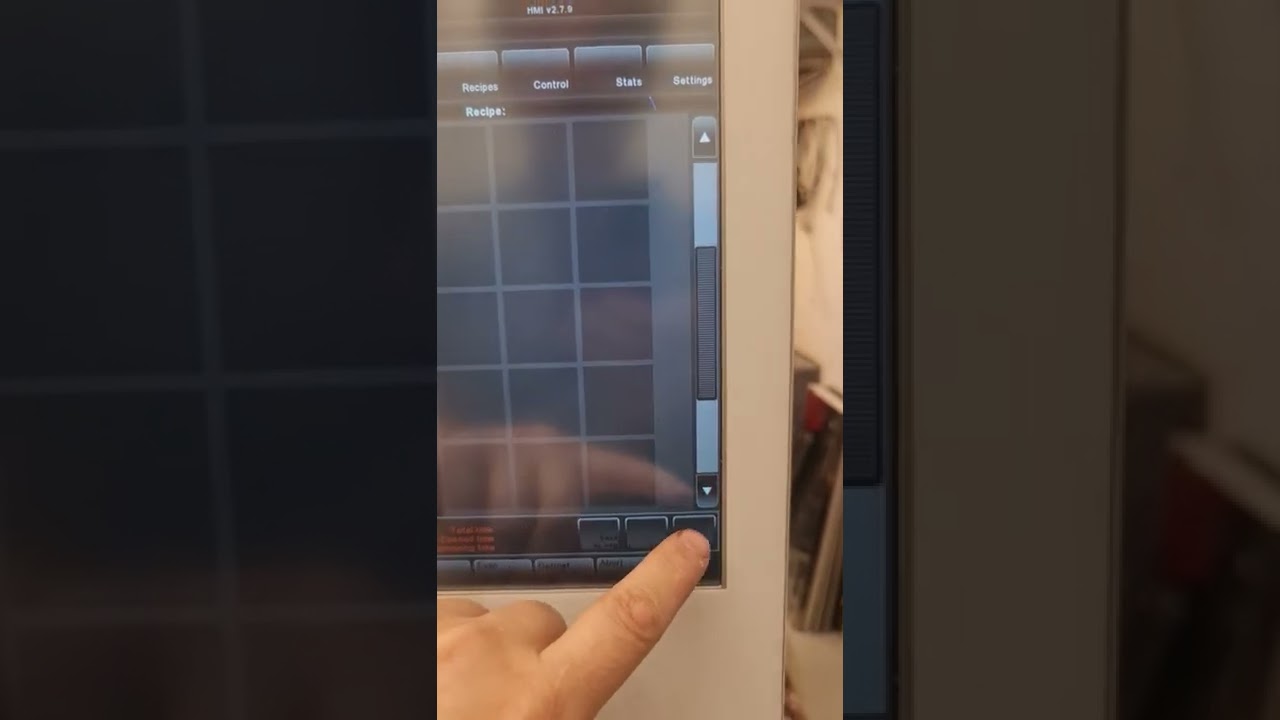

Freeze drying process through drying cycles

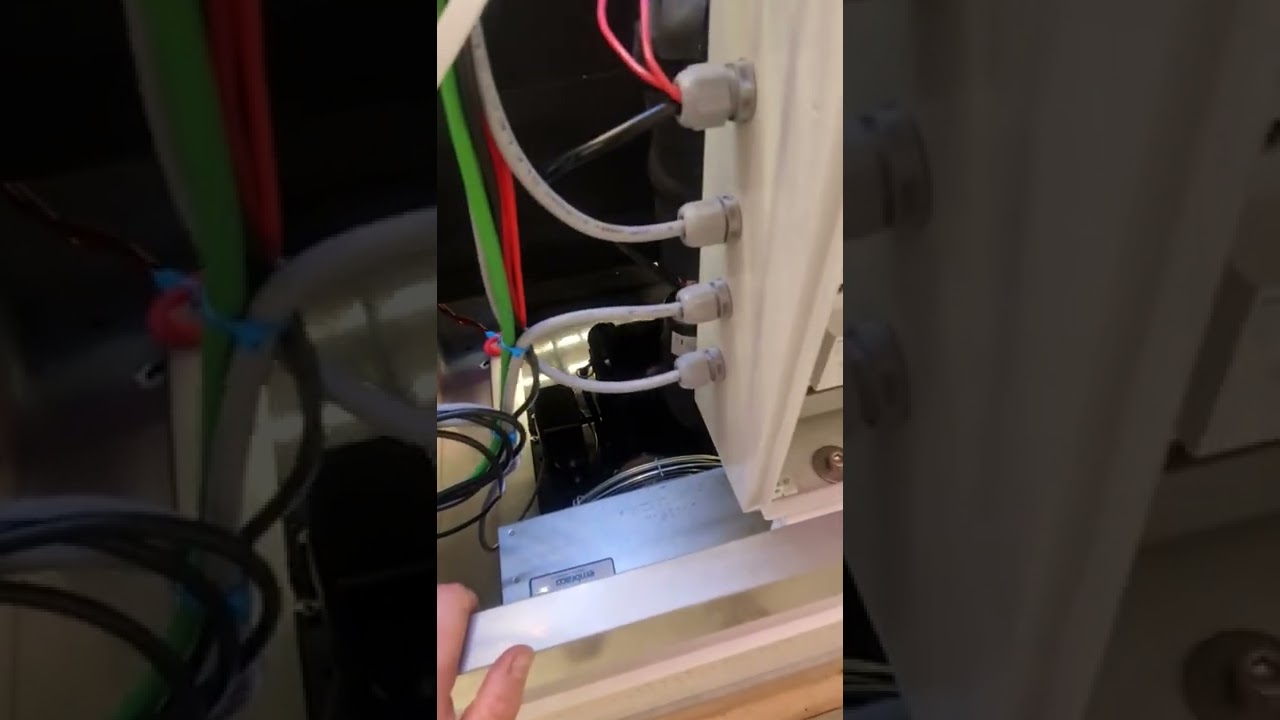

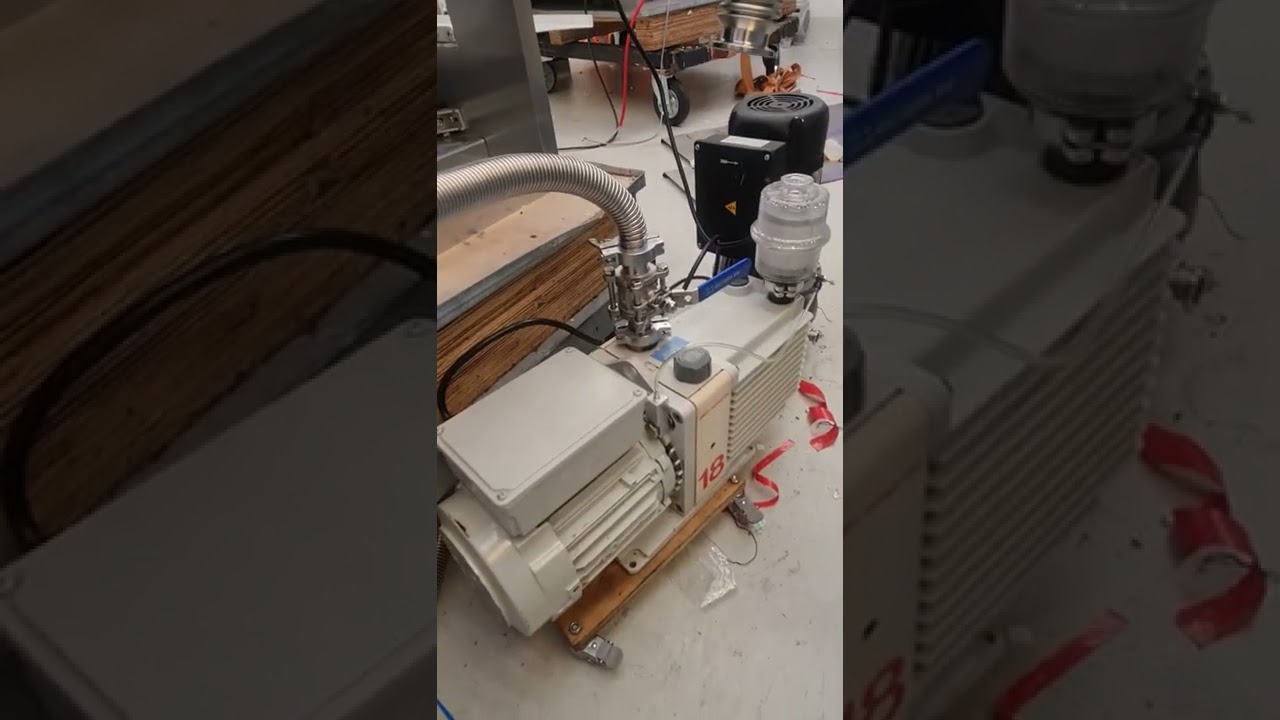

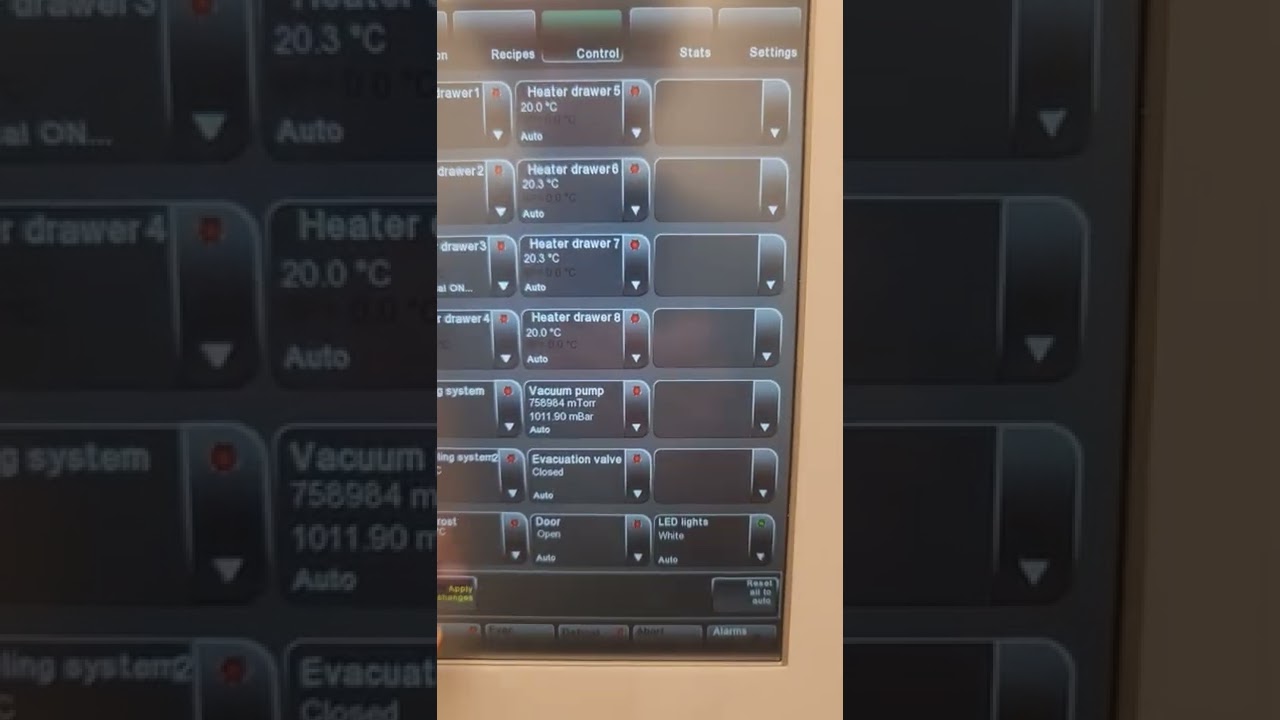

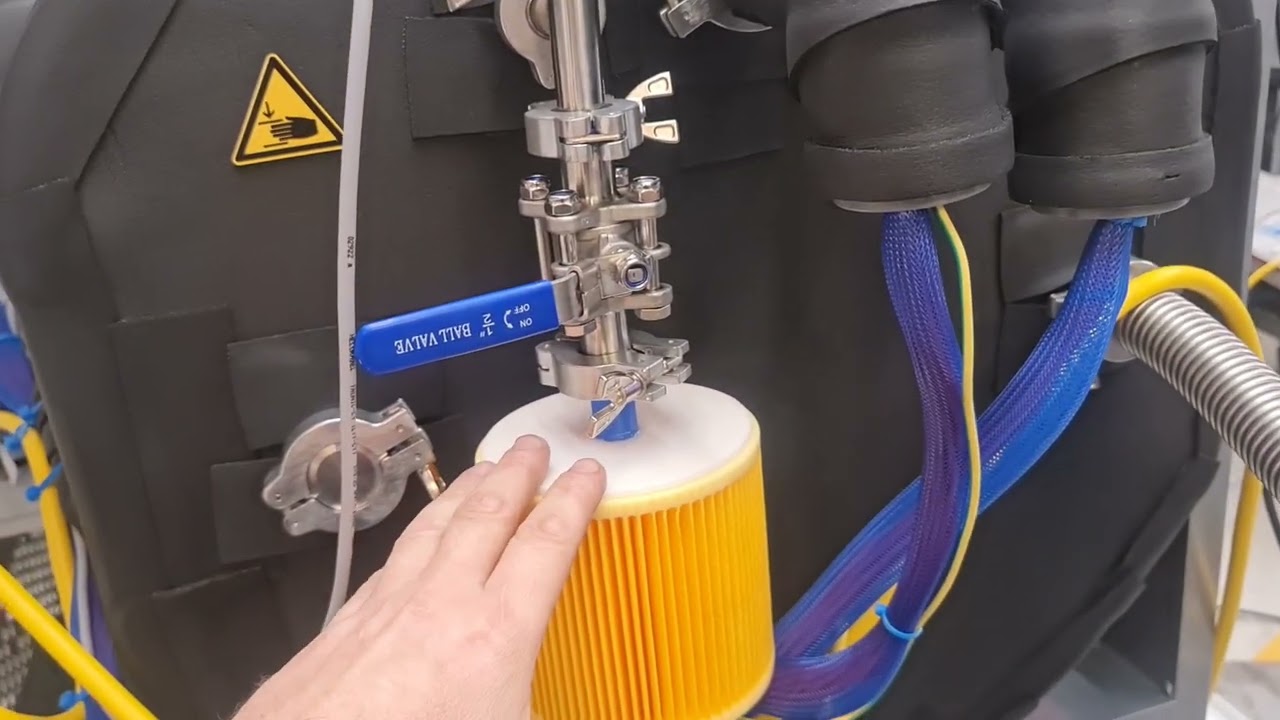

The second stage of freeze drying is called primary drying (sublimation), where the pressure is reduced (a vacuum is created) and heat is applied to the product to allow the water to sublimate. The vacuum promotes sublimation. The condenser provides a surface for the water vapor, in the case of the WAVE freeze dryer the vacuum chamber wall is the condenser to which the water vapor adheres and solidifies in the form of ice. The condenser also protects the vacuum pump from the water vapour. Too much heat at once can affect the structure and shape of the material.

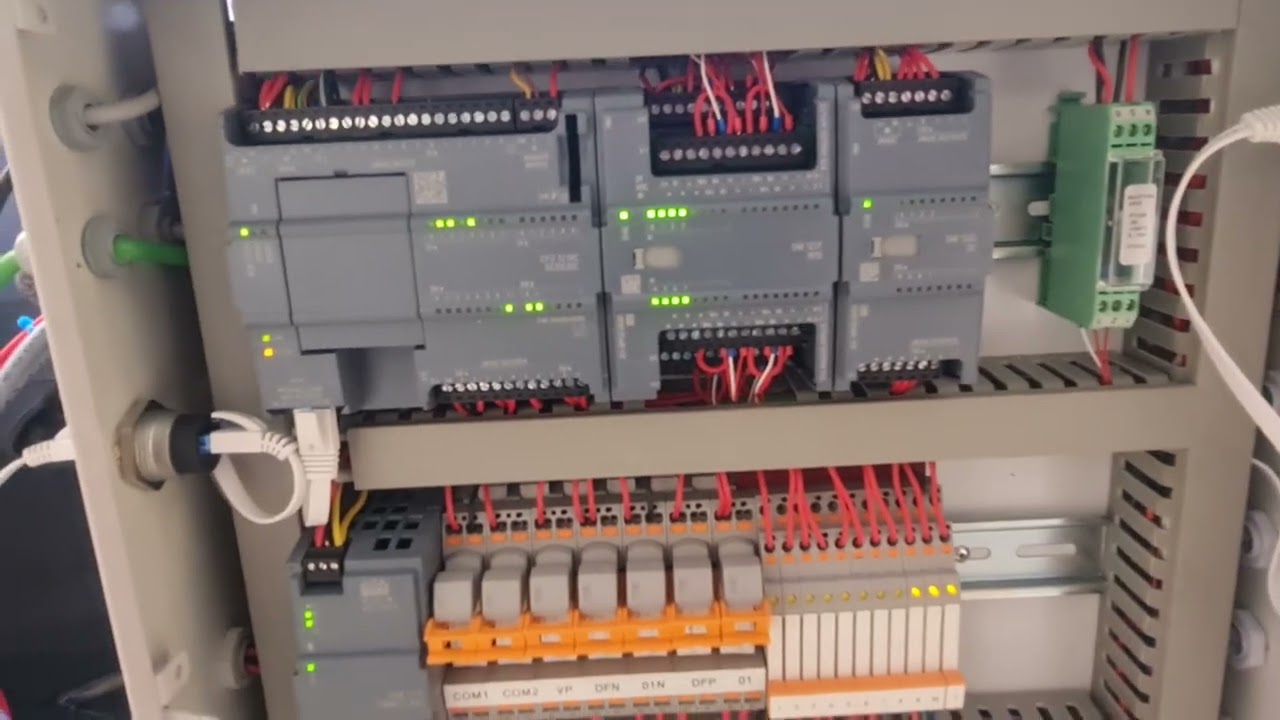

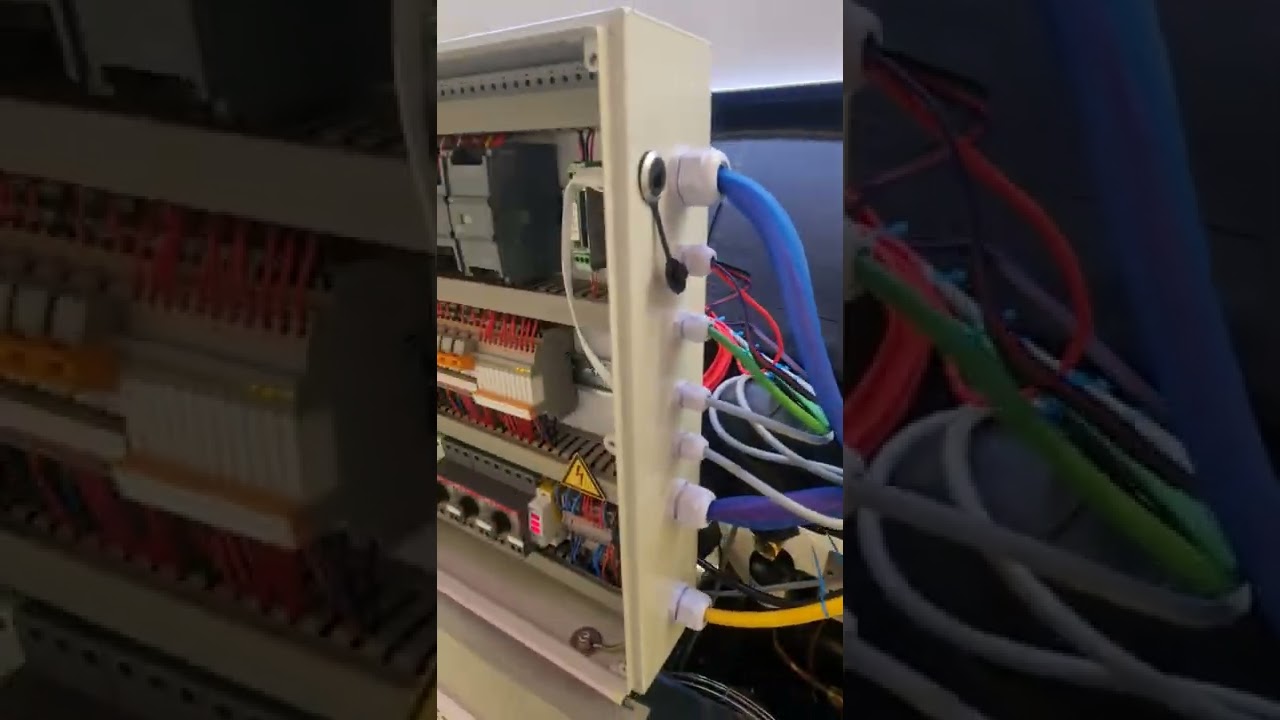

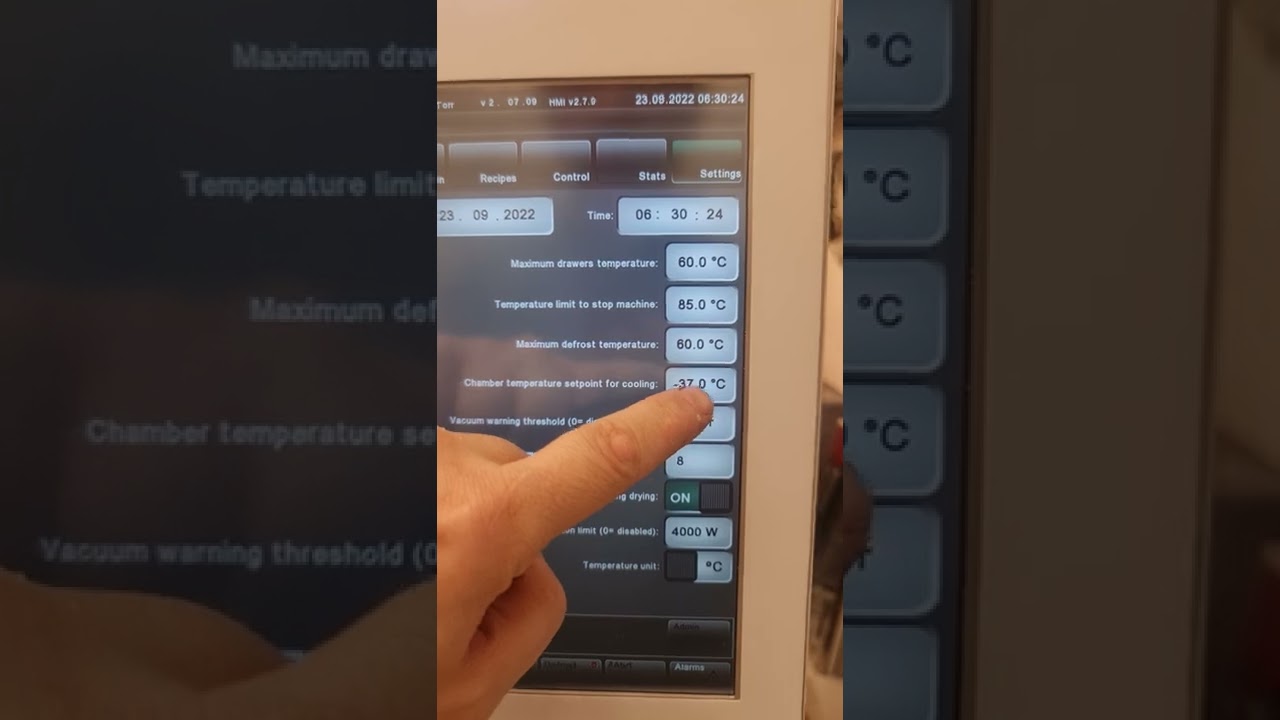

This is followed by the further phases of freeze drying, the secondary drying (adsorption), in which water molecules that are ionically bound are removed. By increasing the temperature in small steps higher than in the primary drying phase, the bonds between the material and the water molecules are broken. These drying stages can, for example, take place at intervals of 10°C and can be flexibly adjusted using the Siemens control of the WAVE freeze dryer. Freeze-dried materials retain a porous structure. After the freeze drying process is complete, the vacuum can be broken before the material is sealed airtight. Most materials can be dried to 1-5% residual moisture thanks to this process.